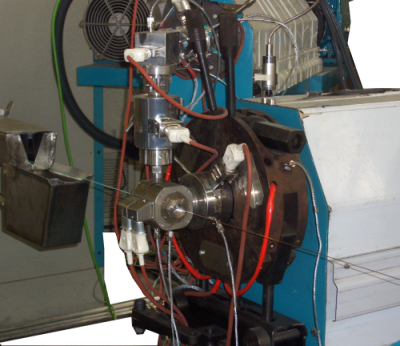

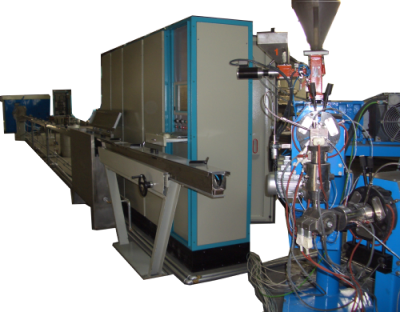

Foam Skin Lines

This is a high speed insulation line for producing foam skin lines. With wire drawing machine, line speed can go up to 1800 meters/minute. With flyer payoff machine line speed can go up to to 1250 meters/minute depending on copper quality.

First zone of the cooling through is fed from hot water tank and moveable with help of a motor. According the foaming process, diameter tester unit is continuously measuring diameter and controlling length of the first zone of the cooling through automatically adjusted by line control software. By this way physical foaming process is controlled and diameter of the cable is kept constant.

There are two extruders, mt type capstan unit, testing devices and automatic dual takeup unit on standard line configuration.

For foam skin process there are two methods available: physical foaming or chemical foaming.

With this line cable diameters between 0,40 and 2,40 mm range is produced as foam skin cable. Also up to 6 mm of insulated cables can be produced.

With standard line foam skin, Solid PE, PVC, XLPE materials are used.

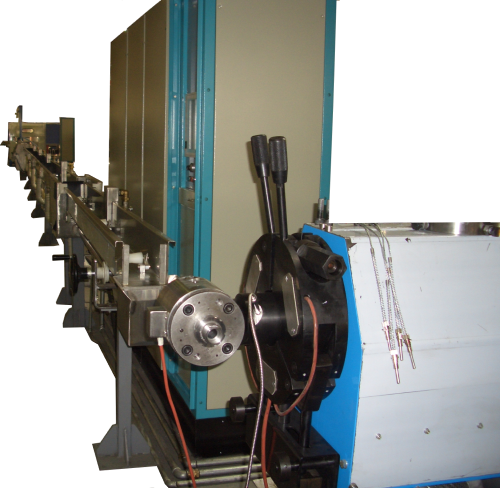

High Speed Insulation Lines

These lines are able insulate solid or multi-core copper wires from 0,4 mm to 6 mm diameters with high speeds.

Line can make insulation of single layer, double layer or with stripe extruded cables.

Line is delivered with standard self centering CH4/6 heads. As an option, bypass equipment is also available with the head.

These lines are stable working, lineer efficiency, low scrap production units.

With the line PVC, PE, HFFR (LSOH), XLPE materials are used as standard and additional materials are available on request.

With this type of lines automobile cables, low voltage cables, installation cables, CAT5 and CAT6 (some types), signal cables, etc. can be produced.

Depending on the cable type to be produced, line speeds can go up to 1250 meters/minute.

Medium Section Insulation Line

With these type of lines, cables with solid and multi-core copper and wires diameters up to 20 mm can be produced. With these lines single layer, double layer and stripe can be produced.

Depending on the size of the final product manual adjustable heads are used on these lines. Optionally, bypass systems for head is also available.

Different types of payoff, takeup, capstan and accumulator machines can be used in the configuration of these lines.

With stable working lineer efficiency extruders, these lines working with lower scrap rates.

Standard lines are using PVC, PE, HFFR (LSOH), XLPE materials.

With different configurations of this types of lines solar cables, low voltage cables, installation cables, flexible cables, etc. are produced.

Line speeds up to 800 meters/minute depending on cable type to be produced.

Larger Diameter Insulation Lines

With these lines cable diameters from 20 mm to 120 mm are produced. With these lines single layer, double layer and stripe can be produced.

Depending on the size of the final product manual adjustable heads are used on these lines. Optionally, bypass systems for head is also available.

Different types of payoff, takeup, capstan and accumulator machines can be used in the configuration of these lines.

With stable working lineer efficiency extruders, these lines working with lower scrap rates.

Lines can use PVC, PE, HFFR (LSOH), XLPE materials.

Depending on cable type and size, line speed can go up to 300 meters/minute.

For Information and Requests

For detailed information, your questions and requests please contact us. Our sales team will reply you in the shortest time.