Color (Masterbach) Dosing

Masterbach Dosing Units

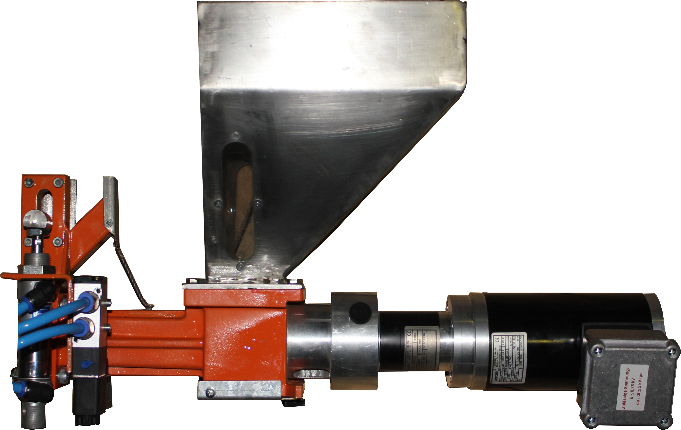

This unit is dosing masterbatch material used for coloring extrusion material. The unit is assembled on extruder with a connection flange. The unit is consisting of a raw material hopper, barrel, screw, motor, and driver. As an option, with the request of the end-user, a connection flange and manual controlling are delivered. In case the unit is asked to be assembled on a "Savsan" production extruder, automatic and manual controls with the software are also available and can be adapted to current systems.Standard masterbatch dosing systems are able to dose between 70 to 7000 gr/hour (according to screw and barrel size different intervals are applied). There are 3 different sizes of screw and barrel.

In order to make color changes faster, two units can be assembled on the extruder. While one unit is working actively, the second unit is cleaned and made ready for a new color.

Multiple Connection (Flange is not included)

Catalyst Dosing

The unit is assembled on extruder with a connection flange (if flange for masterbatch is available, it can be assembled on the same flange). On one flange maximum, 4 units can be assembled.

For Information and Requests

For detailed information, your questions and requests please contact us. Our sales team will reply you in the shortest time.