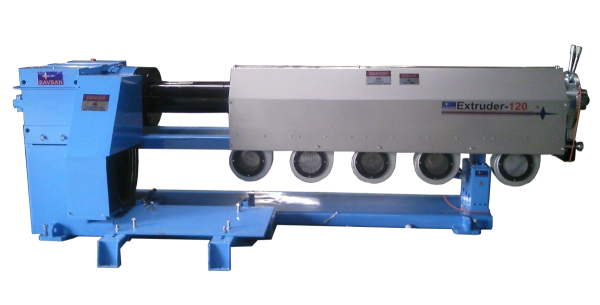

Extruders

Screw

With more homogeneous mixing and melting properties, our screws can process a wide range of plastic materials: LDPE, HDPE, LLDPE, PP, PVC, PU, PA, HFFR, etc. Our special design screws have high capacities and material qualities. We are producing our screws from special nitration steel DIN 1.8550 which has surface hardness between 900 and 1050 HV.Barrel

We are producing our own barrels in our facility with our machine park. We are producing our barrels from special nitration steel DIN 1.8550 which has surface hardness between 900 and 1050 HV.Gearbox

We are producing our own gearboxes specially designed for extruders. Main body is from strong casting steel. Gears are produced from special materials that is maximizing working time, minimizing noise and vibration. It has a hardened casting steel compact structure. Designed and produced to work with high torques without any problems. Gearbox has axial bearings that are suitable to work under high pressures and speeds. Bearings are placed in the front side of the gearbox in order to ease the maintenance process.Heating and Cooling Zones

Barrel is heated by speacial barrel nozzle resistances and cooled with high performance raidal fans. Also in case of necessity, necessary zones of screws and barrels also can also be controlled with oil or water systems.Feeding Zone

With positive high pressure feeding zone, a smooth flow of extrusion materiak is achieved despite the recoil pressure. In the ffeding zone we are using a special groove design. With this design in the end of feeding zone a high pressure is achieved. By this way, performance of extrusion is not affected by head pressure, tools pressure, etc. parameters.Production Processes

We have 5 axis CNC Machining Center, hole drilling machine, honing machine, horizontal grinding, nitration oven, etc. which are necessary to produce barrels, screws and other mechanical parts neceesary for extruders and cable machines. We also have 3D coordinate measuring machine and all other test tools in our quality control laboratory. We are also producing all electric cabinets and software in our facility. By this way, we can make flexible production and necessary customizations requested from our customers. Also able to control all procedures and progresses during production of machines.Optional Units

Pressure SensorPressure and Melt Temperature Sensor

Masterbach Dosing Unit (Single or Dobule)

Catalyst Dosing Unit

Hopper Loader

Raw Material Dryer (Surface Humudity)

Raw Material Dryer with Silicagel

| TECHNICAL DATA** | |||||||||

| Sıra | Type | Screw Dia. (mm) | Length/Dia. Ratio | Max Screw rpm | Max Torque (kNm) | Motor Power (kW) | Heating Zones | Total Heating Power (kW) | Max Barrel Pressure (bar) |

| 1 | EX 30 | 30 | 24 | 140 | 0,35 | 5,80 | 4 | 4,40 | 1000 |

| 2 | EX 45 | 45 | 24 | 135 | 2 | 22 | 4 | 6,90 | 1000 |

| 3 | EX 60 | 60 | 24 | 120 | 4 | 48 | 4 | 12 | 1000 |

| 4 | EX 80 | 80 | 24 | 100 | 5 | 66 | 4 | 19 | 1000 |

| 5 | EX 100 | 100 | 24 | 90 | 10 | 130 | 5 | 27 | 1000 |

| 6 | EX 120 | 120 | 24 | 80 | 20 | 166 | 5 | 31 | 1000 |

| 7 | EX 150 | 150 | 24 | 66 | 28 | 240 | 5 | 37 | 1000 |

| CAPACITY (Kg/hr)** | ||||||

| Or.No. | Type | PVC (Density 1,35) | LDPE | HDPE | PA | PU |

| 1 | EX 30 | 21 | 15 | 16 | 15 | 15 |

| 2 | EX 45 | 80 | 51 | 53 | 51 | 51 |

| 3 | EX 60 | 140 | 90 | 93 | 90 | 90 |

| 4 | EX 80 | 365 | 240 | 245 | 240 | 240 |

| 5 | EX 100 | 560 | 387 | 395 | 387 | 387 |

| 6 | EX 120 | 800 | 575 | 590 | 575 | 575 |

| 7 | EX 150 | 1000 | 880 | 900 | 880 | 880 |

** Important Note: Data given above are for standard units and only for informative purposes. In case machines are procured in a line configuration, according to technical data and requirements of final product, our company is keeping its rights reserved to make modification on these data without any prior modification.

For Information and Requests

For detailed information, your questions and requests please contact us. Our sales team will reply you in the shortest time.