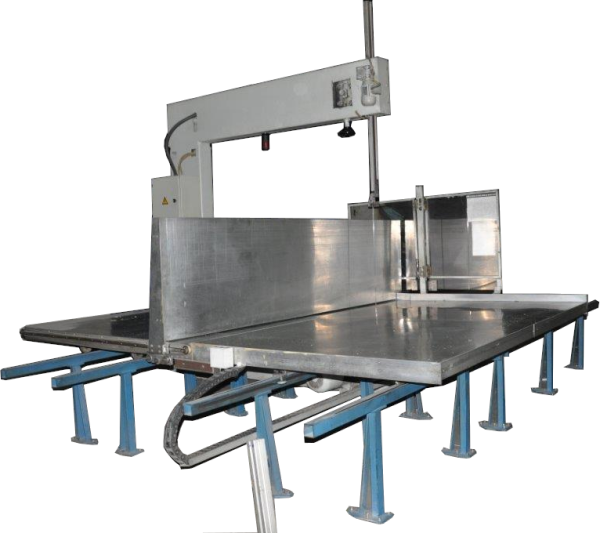

Manual Vertical Cutting Machine

Double Motor Knife Sharpening

Manual Vertical Foam Cutting Machine

There is a blade sharpening system with two grinding motors on the machine. In this way, the blade is always kept sharp as requested.

As the blade is sharpened on both sides, foam blocks can be cut with both forward and backward movement of the table. This increases the capacity of the machine.

A blade guide with a motor is assembled on the machine that is adjusted according to the height of the foam block. This guide system enables the blade to cut foam block smooth.

Foam table is moved forward and backward with the help of the operator.

The machine has the necessary safety sensors and an emergency stop button.

Felt Sizing Unit

Rotary Knife with Piston

Felt Edge Cutting Machine

According to the desired size, the blades can be moved at a certain distance on both sides.

The knives and the surfaces that the knives press on the roll are made of special alloy hardened knife steel. Thus, materials and roll surfaces working against knives can work for a long time. The knives can be sharpened and the roll surfaces are also be grinded to enable materials to be used multiple times.

The pressure of the blades is adjusted by pneumatic pistons and the blades are lifted when desired and the circuit is left out.

It is rotated by the motor in accordance with the pipeline speed under the blades. Thus, it is ensured that the felt is cut properly and moves on the line.

For Information and Requests

For detailed information, your questions and requests please contact us. Our sales team will reply you in the shortest time.