Sample Small Diameter Sheathing Cable

Small Diameter Sheathing Lines

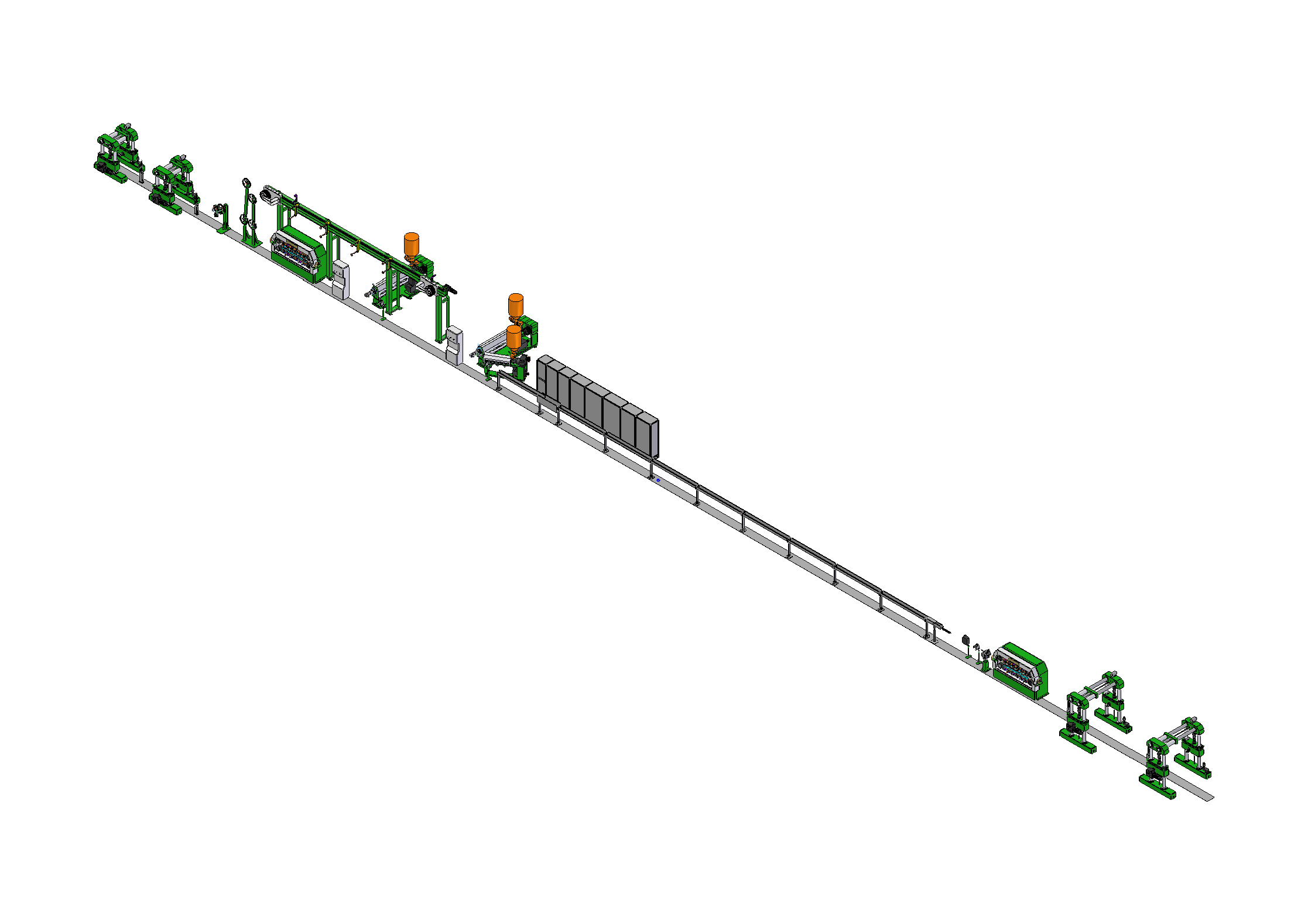

Main line configuration of standard lines are consisting of payoffs, extruders, cooling through, pulling capstan and takeup machines.

Line is controlled by a user friendly software via a touch-screen panel. All main data of machines on the line can be controlled via this software and screen. Line and extruder speeds of the line is automatically controlled with the software. By this way, diameter of the cable surface quality is kept stable and high efficiency with small scrap rates are achieved.

Single layer, double layer and sheathing with strip can be made with these lines.

Optionally additional extruder, takeup and payoff, double layer cooling through, hot water tank, horizontal and vertical accumulators, powdering, etc. machines can be placed on the lines.

PE, PVC, XLPE, HFFR, LSOH (LSZH) materials (additional screw might be necessary for some materials) can be used with standard lines. For other materials please contact us.

Line speed is up to 600 meters/minute in accordance with cable type and diameter.

Sheathing Lines

Depending on the size of the final product manual adjustable heads are used on these lines. Optionally, bypass systems for head is also available.

Different types of payoff, takeup, extruders, caterpillars and accumulators can be used in the configuration of these lines.

With stable working lineer efficiency extruders, these lines working with lower scrap rates.

Line is controlled with line control software via user friendly touch-screen HMI. All main data of the line and machines can be seen and controlled via this touch-screen panel.

Standard lines are using PVC, PE, HFFR, LSOH, XLPE materials.

With different configurations of this types of lines solar cables, low voltage cables, installation cables, flexible cables, etc. are produced.

Line speeds up to 300 meters/minute depending on cable type to be produced.

Sample Line Layout

Tandem Filling and Sheathing Lines

Different sizes of manually center adjusted extrusion heads can be used with these lines according to the diameters to be produced.

On the standard configuration of these lines payoffs, extruders, entry abd exit caterpillars, accumulators, cooling thorough and takeups are used. Powdering units are also used on the line.

Line is controlled with line management software via touchscreen panel. All main data of the line and machines can be input and actual values are screened via this screen. Also sofware makes synchronization of line speed and extruder speed is adjusted automatically according to recipe. Sheathing thickness of cables controlled automatically and by this way stable working and cost effectiveness is achieved. Line is working with lower scrap rates with this software.

PVC, PE, HFFR (LSOH), XLPE materials can be used with these lines.

Line speeds up to 100 meters/minute can be achieved according to cable diameters.

For Information and Requests

For detailed information, your questions and requests please contact us. Our sales team will reply you in the shortest time.